This may come as a shock to you, but finding frame components for a 57 year-old trailer is a little difficult.

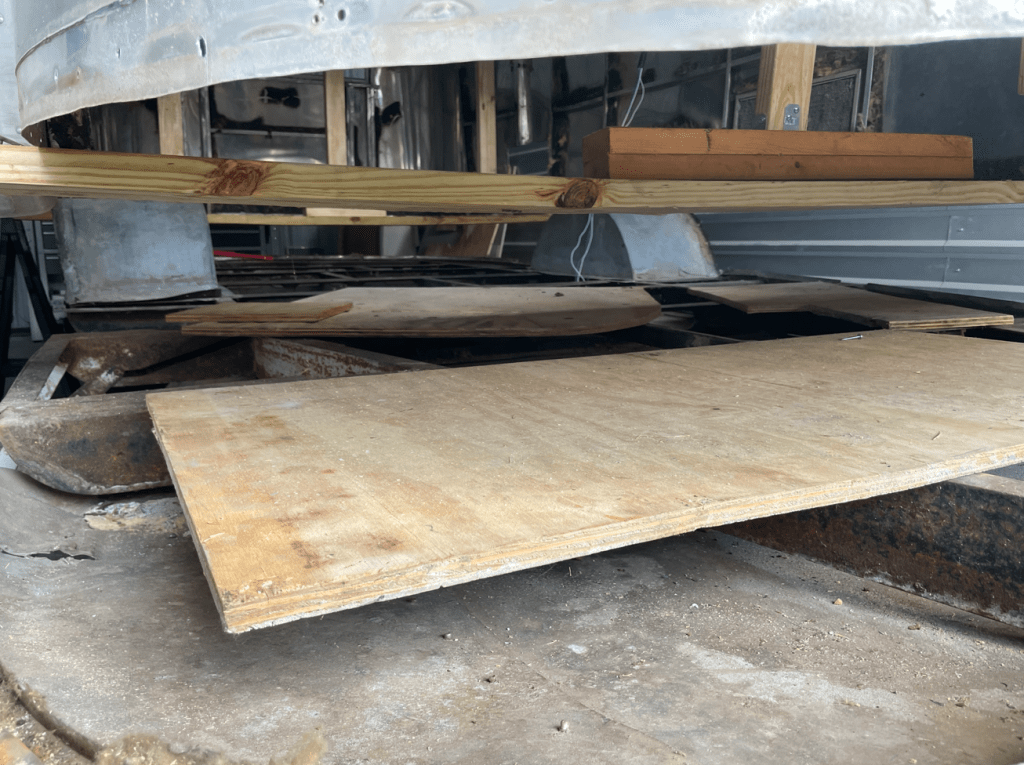

After we got done disassembling and inspecting the frame, we quickly came to the realization that it was in need of repair. There were sections that were severely rusted, and others that had been cut with a cutting wheel.

The first order of business was to remove as much rust as possible, and primer the frame to minimize rust. This was dirty, sticky business in the south Texas heat . . . but to paraphrase Larry the Cable Guy we . . . “got ‘er done”.

Preserving The Frame: After multiple unsuccessful attempts to find a method to grit-blast the frame, we decided to clean it using wire wheels. This worked . . . but boy was it messy and dirty and ucky!

It took about a month, but we got most of the rust off and then put on a coat of primer to keep the frame from rusting in the humid Houston heat.

Note: The above two photos were taken AFTER we welded in the new outrigger and cross-members (Stef is sitting between the two new cross-members). The repair of the frame will be the next post.

As the photos show below, the transformation of the frame was remarkable!